Three Different Types of Industrial Heating Systems

Three Different Types of Industrial Heating Systems.

Industrial heating systems are not just bigger than domestic ones, they're also more complex. They're tasked with keeping people comfortable, but there's more. They often have to keep the fabric of the building and its contents free from condensation, protecting delicate industrial processes and materials as well as people. Your choices for heating a large commercial space are radiant heating (infrared heaters) or warm air heaters, also called air rotation heating. Here's what you need to know.

In a large warehouse or factory, our water heating and/or boilers would be used for Commercial office areas / washroom facilities, rather than the factory itself. Some factories or industries would use industrial boilers for manufacturing processes.

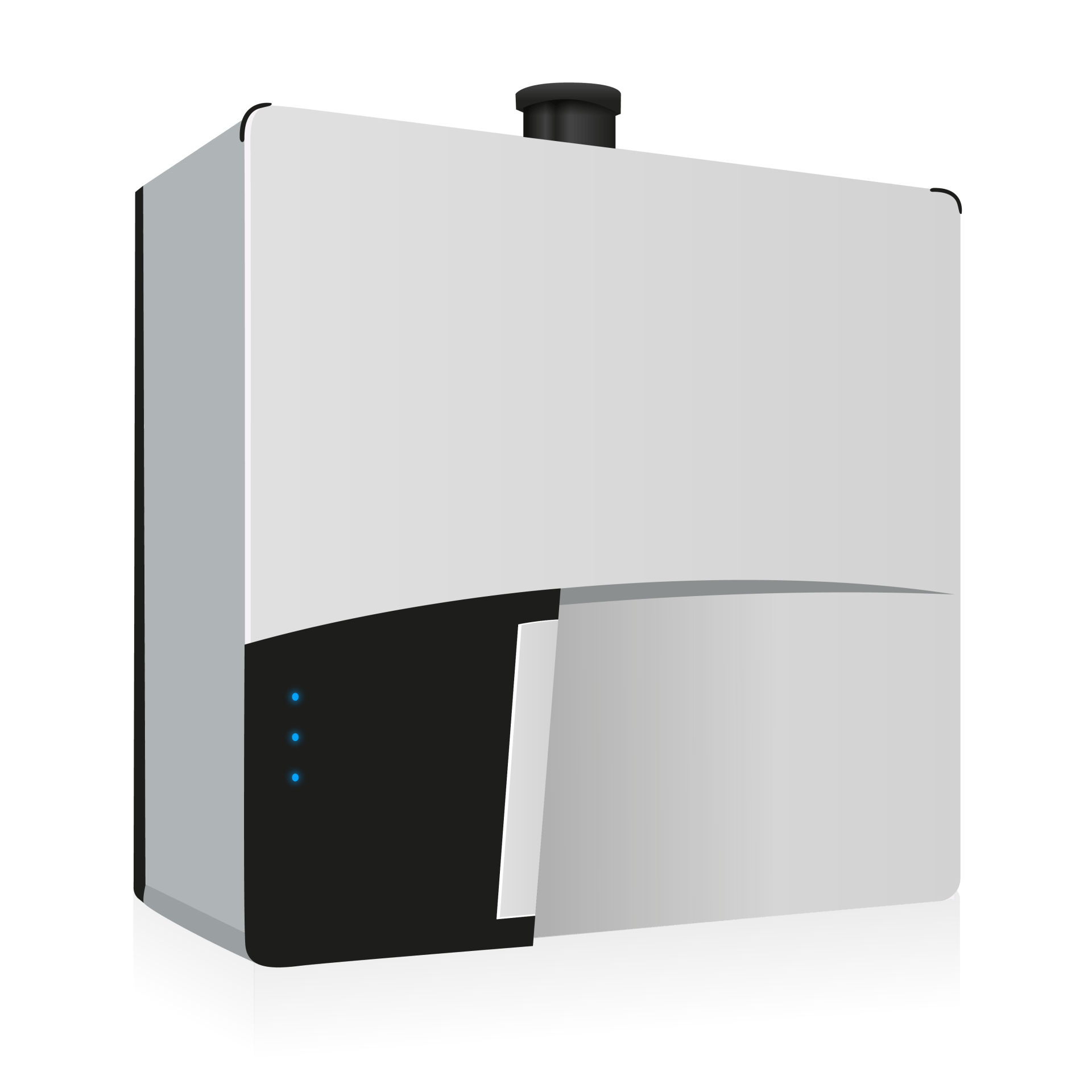

At Factory Heaters, we primarily supply and install warm air heaters which are suspended at high level, but we can also supply reliant tube heating, warm air cabinet heaters or Air rotation units. An air rotation heating system works in a completely different way from most other warm air heating systems. A high airflow, low air velocity unit positioned at floor level draws in cool air at floor level and discharges it at high level across the roof space. The units “rotate” the cool air normally located at floor level, and mixes it with the warmer high level air causing it to fall and be drawn back down to low level by the constant air re-circulation. Heat is distributed evenly, both horizontally and vertically, without the need for de-stratification fans.

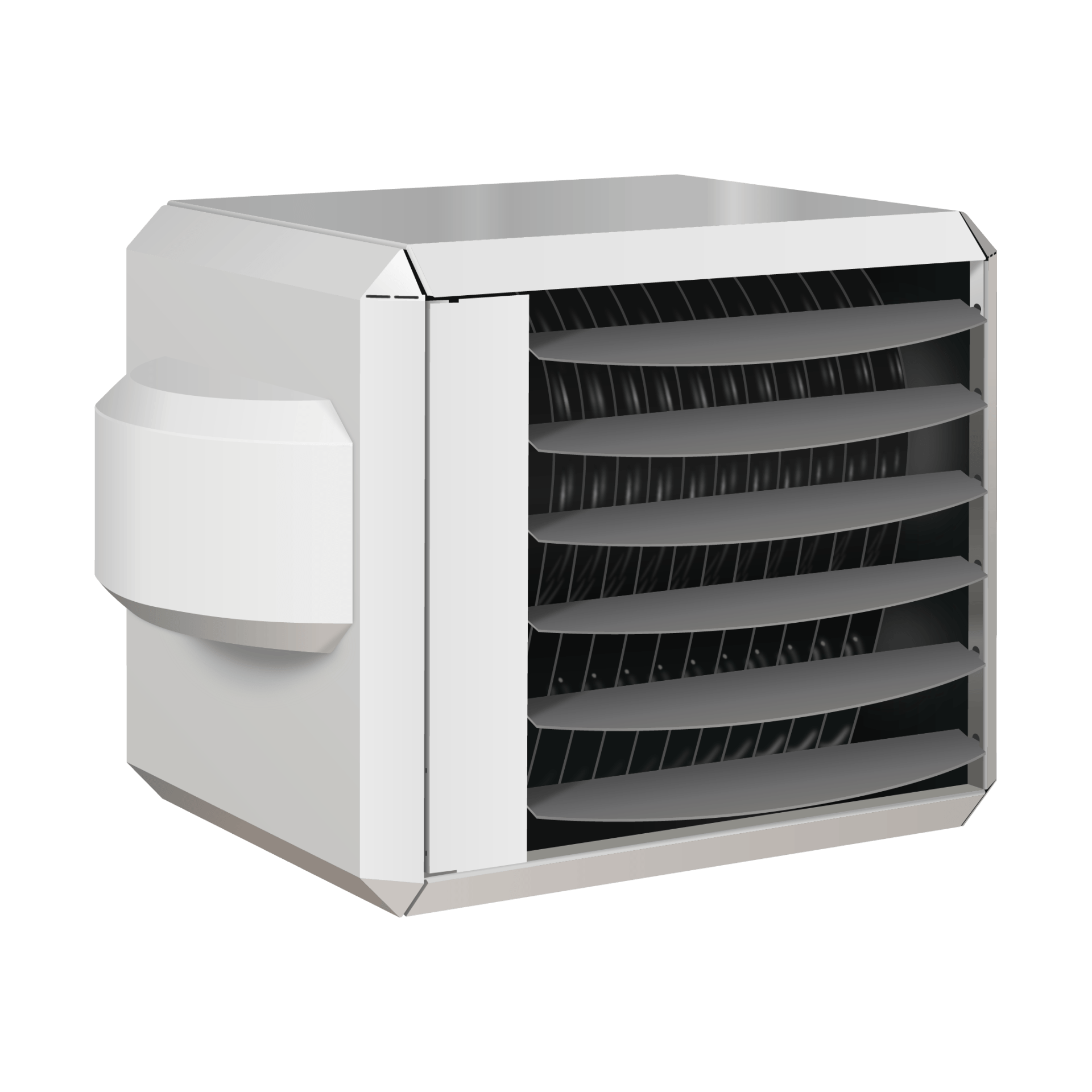

About warm air heaters – Industrial heating using air exchange.

A warm air space heater's fan pulls air over a heat exchanger, transferring it between two or more liquids. The heat source could be anything from circulated hot water inside the heater itself to an electric element or an oil or natural gas burner. The system warms the air and distributes it evenly, making tech like this ideal for places where a constant temperature is essential.

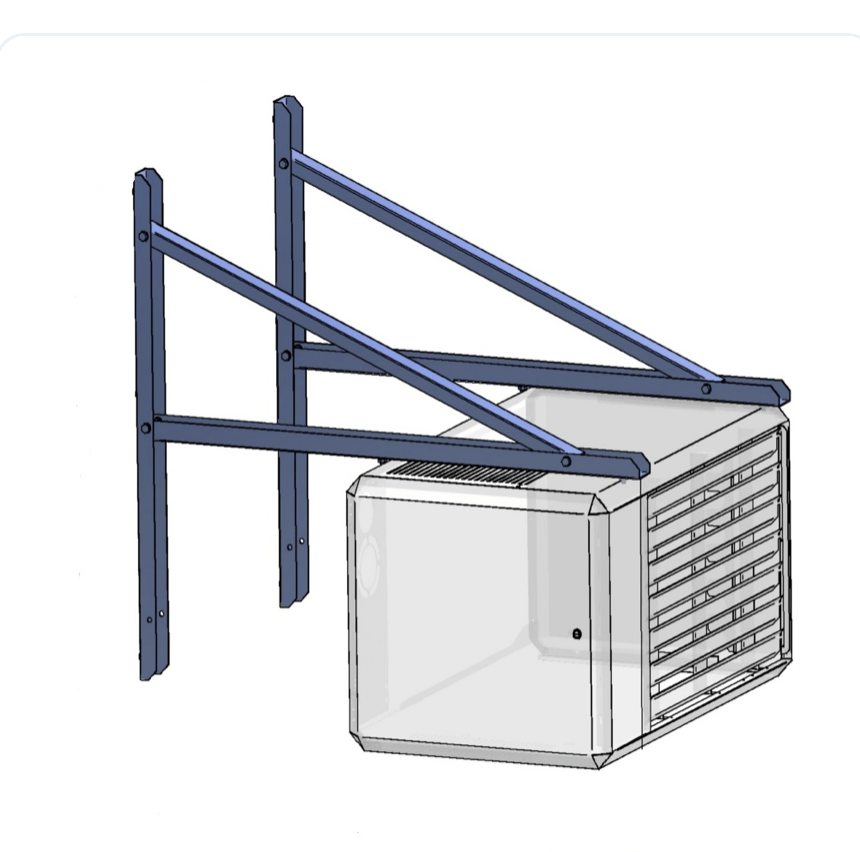

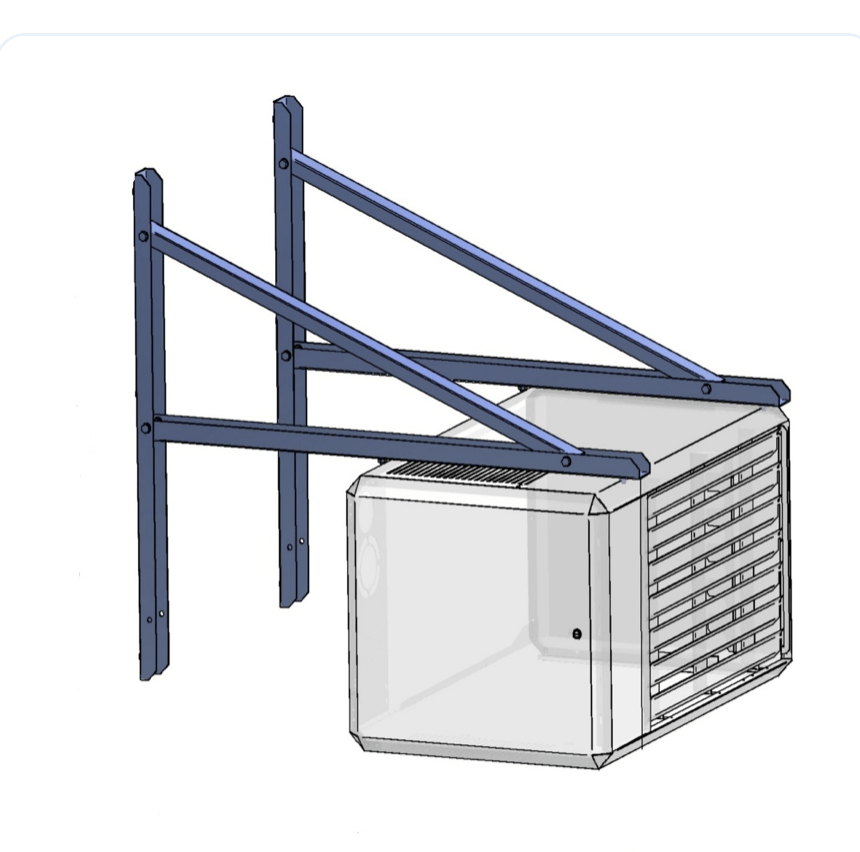

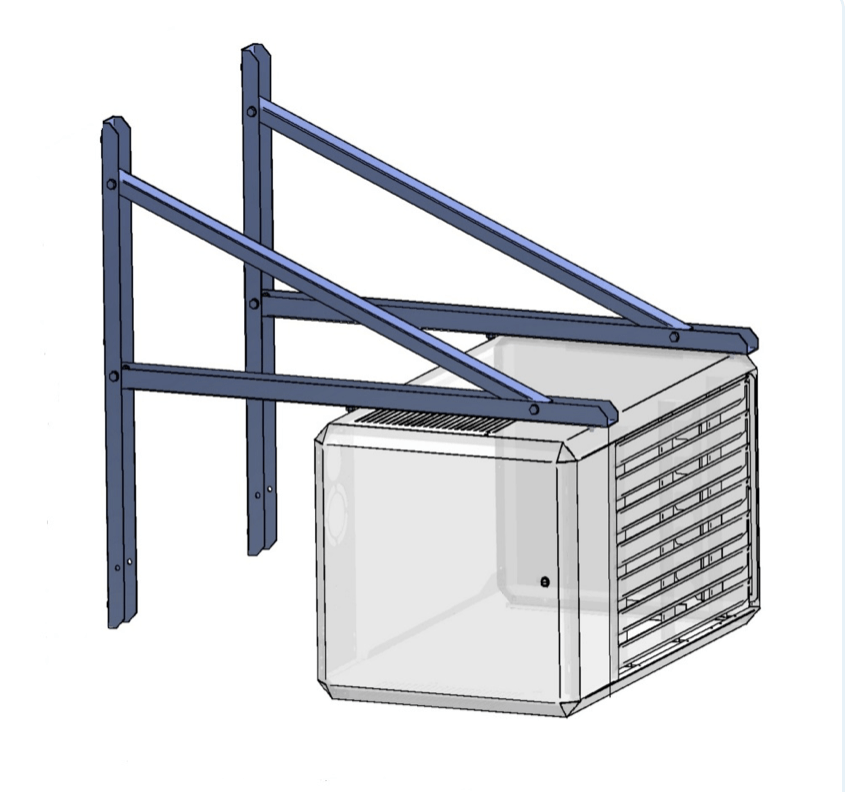

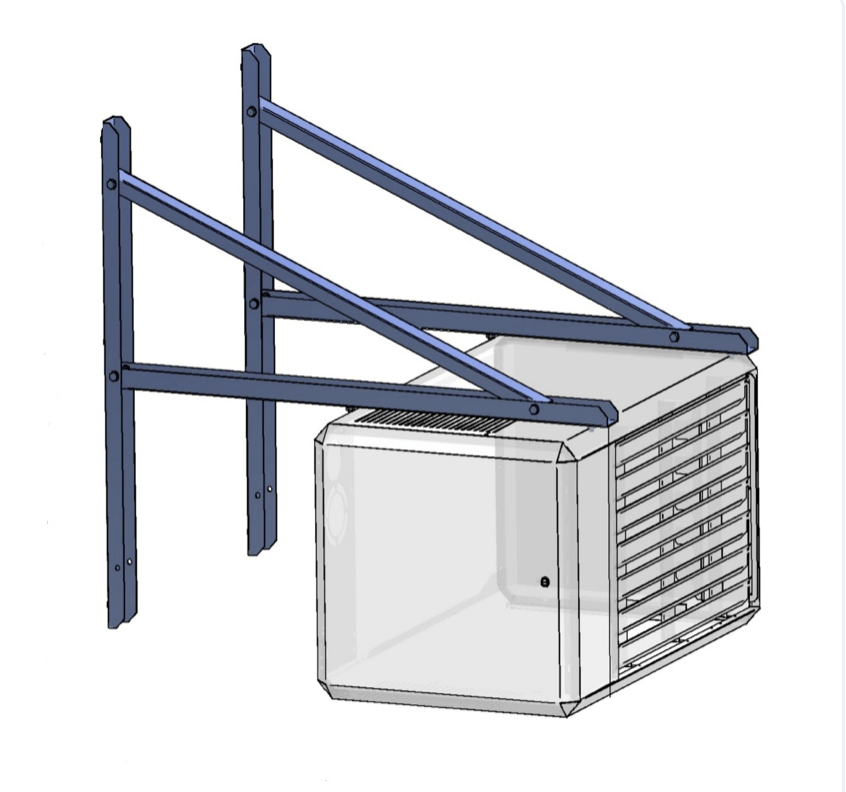

You can mount some warm air heaters on walls or suspend the units from ceilings. Others are designed to stand on the floor. The floor-standing models either use nozzles to direct the heat around the immediate area, or are connected to pipes that distribute the air over a bigger area. Your choice depends on the layout of the premises and the useable floor and ceiling areas. If you don't have space on the floor, maybe you can hang it from the ceiling.

As warm air rises, cold air falls, so in large, high buildings the effect is exaggerated, with valuable warmth getting trapped in the roof space leading to cold zones at floor level. Heat losses can be increased by around 20% unless an adequate means of de-stratification is designed into any high bay heating system. One solution is to install high level de-stratification fans in conjunction with the suspended

warm air heaters, forcing the air back down to lower levels.

About destratification heating – Harnessing thermal destratification

Destratification heating is all about thermal destratification, mixing the air inside a building to get rid of 'strata' or layers of air at different temperatures, created when cool air falls and warm air rises. This makes it a challenge to heat high ceilinged buildings at floor level where employees are. And when your building is cold and uncomfortable, productivity plummets. Destratification system heater fans re-circulate the warm air to even up the temperature from floor to ceiling.

Air rotation heating – No need for expensive pipework

Air rotation heating works in much the same way, moving large amounts of air at low speed and controlled temperatures. The cooler air under the heater is constantly drawn through it, destratifying it. In this case you won't need destratification fans up in the ceiling because the air is already being circulated. Most of the time all you'll need is one heater making it cost effective– and there's no expensive pipework.

Air rotation heaters are great for creating a constant background temperature as well as for frost protection. There's no risk of condensation forming or damage from moisture. And it's a low cost install because it's duct-free. Better still this type of industrial heating is economical to run, making use of heat that would otherwise be wasted, trapped up in the roof. Add simple wall mounted controls and quiet operation and you can see why air rotation heating is a popular choice of industrial heaters.

An air rotation heating system works in a completely different way from most other warm air heater systems. A high airflow, low air velocity unit positioned at floor level draws in cool air at floor level and discharges it at high level across the roof space. The units “rotate” the cool air normally located at floor level, and mixes it with the warmer high level air causing it to fall and be drawn back down to low level by the constant air re-circulation. Heat is distributed evenly, both horizontally and vertically, without the need for de-stratification fans.

About radiant heating – Suspended radiant tubes and plaque heaters

Radiant heating is where you can feel the source of the heat, like a real fire or wood burning stove. The closer you get, the warmer it is. In a commercial heating context this usually means radiant tubes or radiant plaque heaters suspended from the roof or ceiling. Their high temperature surfaces send out heat as infrared radiation, which heats anything exposed to it. It doesn't directly warm the air.

Interestingly this kind of heating also benefits from the presence of people and objects, including the floor, all of which send the temperature higher by acting as secondary heaters. You'll find the air temperature with infrared heaters is lower than warm air heating. But as long as people are near enough to the direct source of heat, all is well. If not, you may need to change the layout of the space to keep everyone comfortable.

The main benefit of radiant infrared heaters is it cuts heat loss where doors are opened and closed a lot, places like loading bays. Everything the heating has warmed stays warm.

Which industrial heating system do you need?

Your ideal industrial heating system depends on the

space and what it’s used for. We're always happy to discuss the ins and outs from an expert perspective. Just

get in touch for sensible advice from the professionals.

Industrial heating systems

Share.

Comment.

Latest.