Common Industrial Heating Problems & How to Fix Them

Introduction: Solving Your Industrial Heating Headaches

When your factory's heating system fails, productivity plummets. From sudden breakdowns to soaring energy bills, heating problems cost UK businesses thousands yearly. The good news? Most common issues have straightforward fixes - especially when using reliable systems like Winterwarm, Rinnai and ATAG industrial heaters.

This comprehensive guide covers:

✅ Top 5 industrial heating failures (and how to fix them)

✅ When to DIY vs call heating engineers

✅ Preventative maintenance schedules

✅ Premium solutions from Winterwarm, Rinnai and ATAG

Let's restore your factory's warmth and efficiency!

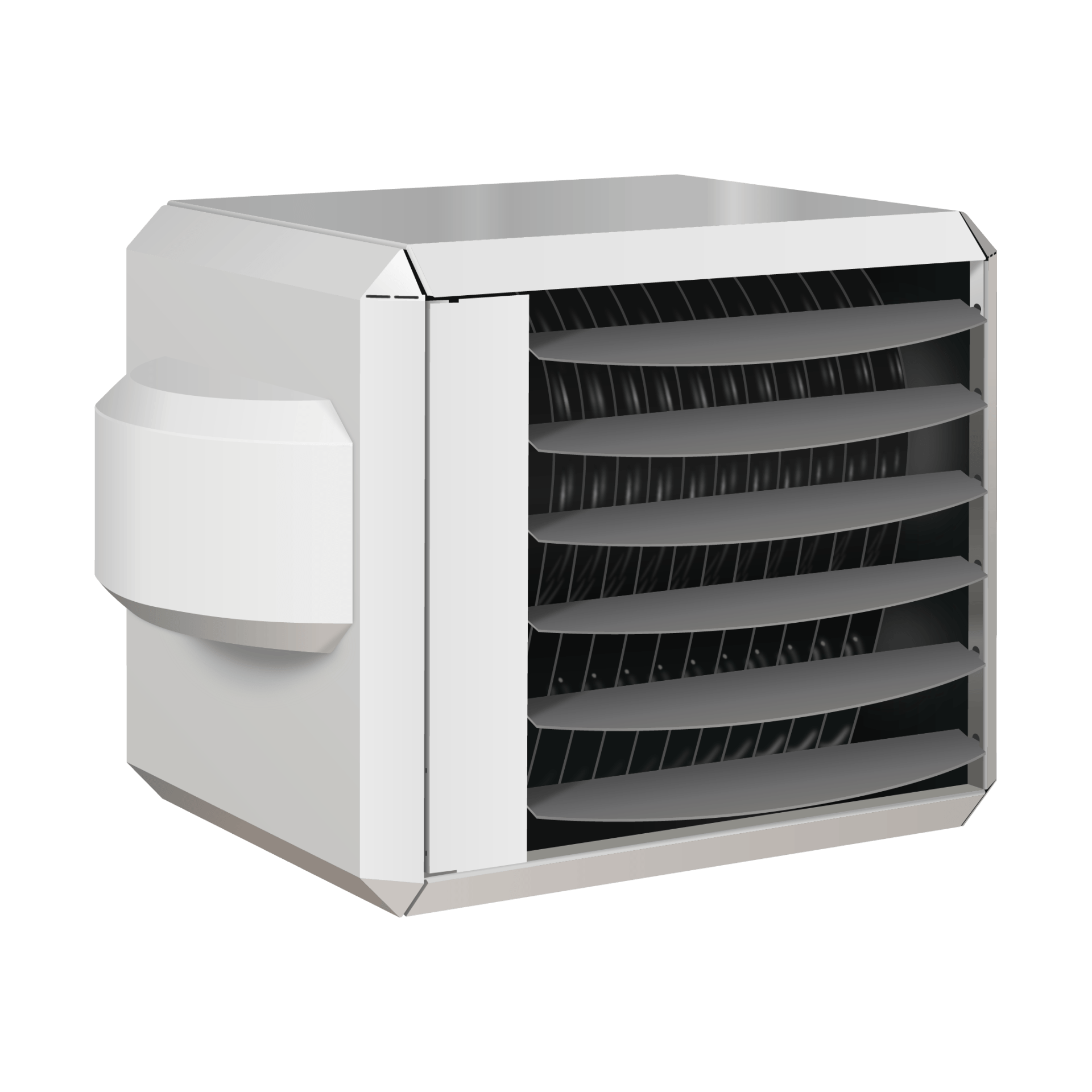

Problem #1: Inconsistent Heating (Hot & Cold Zones)

Why It Happens:

- Poor heat distribution from undersized units

- Obstructed airflow from poor unit placement

- Inadequate insulation

Winterwarm Solution:

The Winterwarm WWH Series offers:

✔ Adjustable louvers for precise airflow direction

✔ Powerful centrifugal fans for even distribution

✔ Thermostatic controls to maintain consistent temps

Pro Tip: Position units at 45° angles in corners for optimal coverage.

Problem #2: Heater Fails to Ignite (No Start-Up)

Why It Happens:

- Faulty ignition system

- Gas supply issues

- Tripped safety cut-outs

Rinnai Solution:

Rinnai's EX Series features:

✔ Dual spark ignition for reliable starts

✔ Automatic fault diagnostics

✔ Built-in gas pressure monitoring

Troubleshooting Steps:

- Check gas valve is open

- Reset power supply

- Inspect ignition electrode (clean if corroded)

Problem #3: Excessive Energy Consumption

Why It Happens:

- Old, inefficient heaters

- Lack of zoning controls

- Heat loss through poor insulation

ATAG Solution:

The ATAG Q Series delivers:

✔ 94% thermal efficiency

✔ Modulating burners that adjust to demand

✔ Weather compensation controls

Case Study: A Birmingham metalworks cut gas usage by 37% after switching to ATAG Q heaters.

Problem #4: Frequent Cycling (Short Run Times)

Why It Happens:

- Oversized heater capacity

- Faulty temperature sensors

- Dirty air filters

Winterwarm Fixes:

✔ Load calculation before new installations

✔ Regular filter changes (every 500 operating hours)

✔ Sensor calibration checks during servicing

Best Practice: The Winterwarm WMH Series features multi-stage firing to prevent short cycling.

Problem #5: Unusual Noises (Banging/Whistling)

Why It Happens:

- Loose internal components

- Air in hydronic systems

- Combustion issues

Rinnai & ATAG Solutions:

✔ Rinnai's quiet combustion technology (under 55dB)

✔ ATAG's hydraulic balancing valves prevent air locks

✔ Annual professional servicing recommended

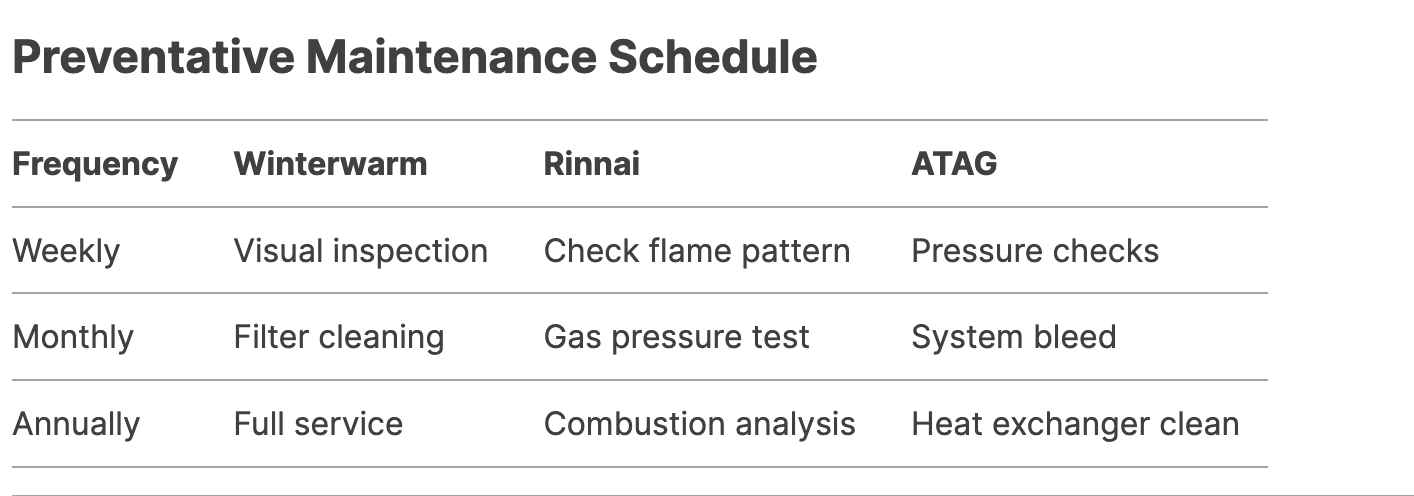

Preventative Maintenance Schedule

When to Call the Professionals

⚠ Gas smell - Evacuate and call Gas Safe immediately

⚠ Electrical faults - Don't risk DIY repairs

⚠ Persistent error codes - Manufacturer expertise needed

Why Choose These Premium Brands?

Winterwarm

✅ British-made reliability

✅ 5-year warranty options

✅ Custom configuration services

Rinnai

✅ Global heating specialists

✅ Industry-leading efficiency

✅ Remote monitoring options

ATAG

✅ Dutch engineering excellence

✅ Ultra-low NOx emissions

✅ Smart heating controls

Final Recommendation

Don't let heating failures disrupt your operations. Investing in quality Winterwarm, Rinnai or ATAG systems prevents costly downtime while improving efficiency.

Next Steps:

- Identify your specific heating challenges

- Compare models in our online store

- Contact our experts for personalised advice

Browse Solutions Today:

Winterwarm Heaters |

Rinnai Systems |

ATAG Commercial Range

Need Urgent Assistance? Call our heating helpline: 0800 123 4567 (24/7 support for commercial clients)

Share.

Comment.

Latest.