System Boiler: Everything You Need to Know

There are three types of boilers which all operate in different ways, namely:

2. System boilers

3. Regular boilers (Heat only)

What is a System Boiler?

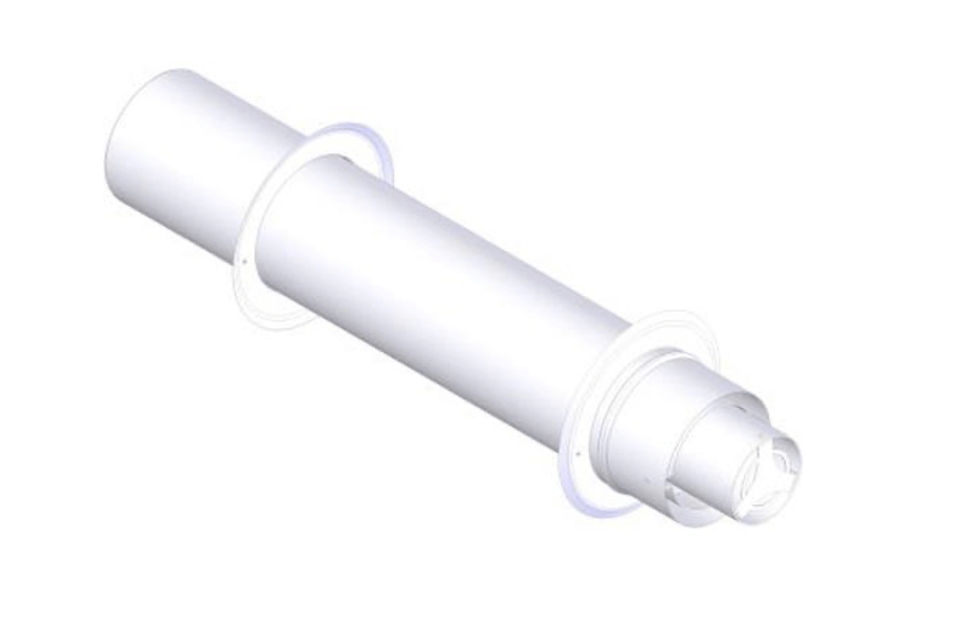

A System boiler is a type of boiler where there are greater demands for heating and hot water, such as for commercial applications or properties with more than one washroom. By featuring a separate cylinder for storing water, system boilers are able to provide a constant supply of hot water throughout the premises, unlike combi boilers which can only heat water on demand.

System boilers heat the central heating system while also supplying hot water to the storage cylinder. They operate in the same way as a regular boiler in that it needs to hold hot water, but they get their water straight from the main supply. This method allows them to be much more modest than traditional boilers while delivering a large volume of heated water to the property.

Slide title

Write your caption hereButton

How Do System Boilers Work?

System boilers are completely different to combi boilers as they are not connected to the cold mains. A coil in the cylinder carries the central heating water at high temperature through the cylinder, heating its contents, allowing the now heated water to be transferred to multiple taps and showers at once. They can usually heat both the radiators in the property at the same time as the cylinder, ensuring no loss of comfort. Essentially, thats how system boilers work.

What are the

benefits of a System Boiler?

System boilers combine the most favourable parts of regular and combi boilers, which means they have several advantages, such as:

- Easy installation procedures

- Good for properties that have a high hot water demand, i.e multiple showers, as the unvented tank can deliver good hot water flow rates to multiple outlets simultaneously

- They are excellent for the high demands of hot water

- Stronger and improved water pressure

- They are economical and fast

- You do not need a cold-water feed tank

- It is compatible with solar thermal

Easy Installation Procedures

System boilers may be installed more easily, quickly, and neatly than a traditional boiler. How? This is because a system boiler incorporates several of the required elements of a hot water and heating system. The device is smaller due to the integrated materials, and it only needs a cylinder that you can place in an accessible cupboard.

They Are Excellent for High Demands of Hot Water

Since a system boiler utilises a large tank of available water, you can use numerous taps at the same time without losing any pressure. It is perfect for larger or busy Commercial properties with multiple washrooms.

Powerful and Improved Water Pressure?

As the primary water supply is provided by the mains instead of a tank, the water flowing out of your taps will be at a higher pressure than ordinary boilers, which rely on gravity to carry water down the pipelines.

They Are Economical and Fast

A pump is already incorporated in system boilers, meaning they respond rapidly and have lower operating expenses.

You Do Not Need a Cold-water Feed Tank

A system boiler does not need a cold-water feed tank and expansion and feed tank, meaning it may be used with pressurized cylinders. This feature saves space while still allowing you to have an adequate system boiler in a smaller property.

It Is Compatible with Solar Thermal

If producing hot water using solar is a priority for you, system boilers are a viable option. The cylinder or tank that contains hot water may be modified to use solar energy to heat the water.

What are the

disadvantages of System Boilers?

Despite the various advantages, there are certain disadvantages when using system boilers as well:-

They Take Up Significant Space

Even though a cold-water feed tank is not required, a system boiler takes up additional room than a combination boiler. This is because you require a hot water tank. The appliances themselves do, however, take up less room than traditional boilers.

You Need to Insulate the Cylinder

The hot water temperature in the cylinder progressively reduces over time. It is highly recommended that the cylinder should be insulated to assist in decreasing heat loss. A properly insulated cylinder retains heat, resulting in not just hotter water for extended periods but also reduced electricity waste. Insulating the hot water tank is usually inexpensive and simple; thus, this is more a concern than a drawback.

The Size of the Hot Water Tank

The size of the cylinder or tank determines how much hot water you may utilize. You have to wait for extra water to heat up after the cylinder is emptied. Depending on the boiler, this procedure could take anywhere from 20 to 30 minutes.

You Do Not Get Hot Water Immediately

When a great deal of hot water is utilized, the warm water can run out since it is contained in a cylinder or tank that will only store a specific amount of water. Before your property has hot water again, a system boiler will have to heat additional water and refill the tank.

What are the differences between a

Combination Boiler and

System Boiler?

Whilst combi boilers can supply heat and hot water, they are not well suited to properties that have a high demand for hot water as they are only designed to support one outlet at a time. As combi boilers typically switch the burner from heating to hot water when there is demand, heating performance can also be impacted in properties with high demand.

The Differences Between a System Boiler and Regular Boiler

A regular boiler is known by a variety of names, including conventional, open vent, and heat-only. They are basically an older version of system boilers so are frequently seen in older properties. Regular boilers, unlike a system or combination boiler, does not get its water from the main supply. Expansion and feed tanks must be built in the loft area instead for these systems to operate.

Is a System Boiler the best solution for your Commercial Property?

The size of the Commercial property, as well as the demand for hot water and heating, determine which boiler type is the best option for your needs. Combination boilers take up the least amount of space, while regular boilers take up quite a lot. A system boiler is in the middle of the range because they require a hot water cylinder; however, they do not require additional tanks.

How to Compare Different System Boilers

When comparing the available options on the market, consider the following characteristics of each boiler:

- Efficiency

- Output rating

- Hydrogen Ready

- The costs

- Warranty

- Engineer or technician reviews regarding heating

- Timing and heating controls

- Customer reviews

The Bottom Line

Combi boilers and system boilers differ from one another; however, both are suitable for different circumstances. You need to find the best option for your Commercial application depending on the various factors to consider. You need to consider the pros, cons, and costs of each boiler before making your final decision. You need to think about the future and ensure that your appliance is Hydrogen Ready (blended for 80% Natural Gas / 20% Hydrogen) in support of Governmental efforts to reduce carbon emissions.

Combi or system? Which one is it going to be?

FACTORY HEATERS LTD will have the heating / hot water solution for you

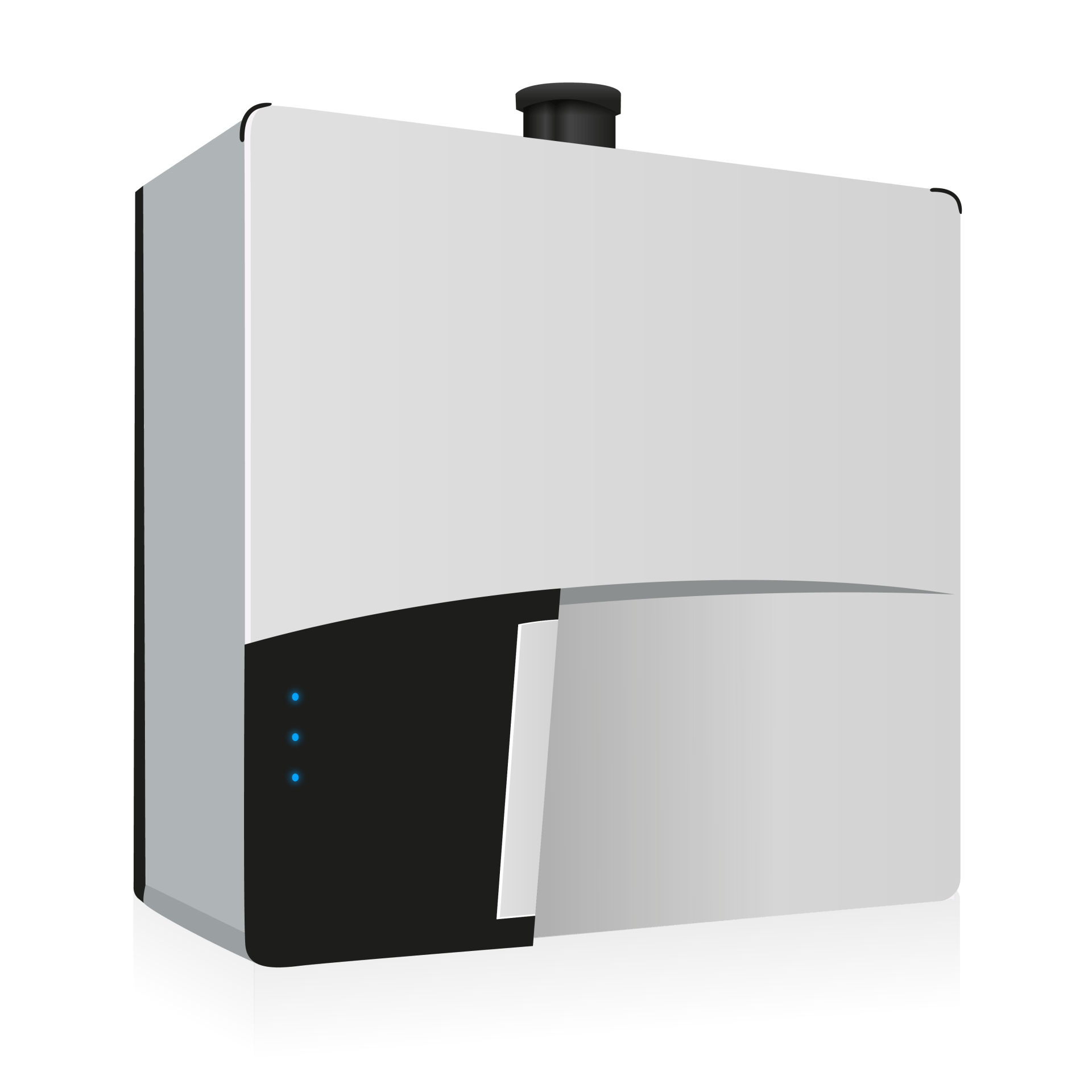

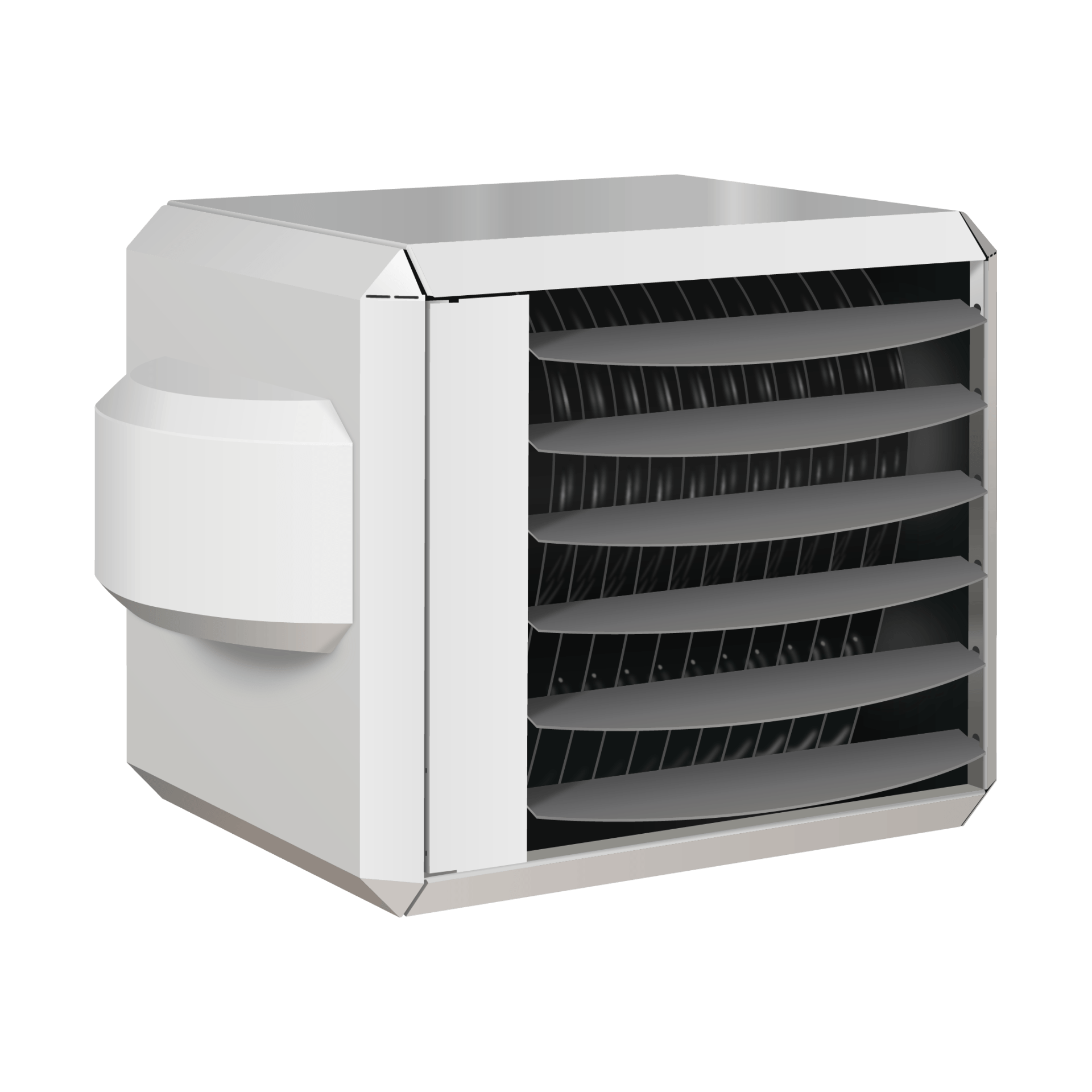

OUR SYSTEM BOILERS FOR SALE.

Comment.

Latest.

Would you like a bespoke heating or hot water solution?

Get In Touch

Established and experienced experts available for Commercial or industrial heating and hot water requirements. Get in touch for all your needs.