Keep Your Industry Warm All Winter: With Condensing Warm Air Heaters!

To keep your industry warm all winter while maximising efficiency, consider condensing warm air heaters. These systems operate by capturing and reusing heat, significantly reducing energy consumption and emissions. They're designed to provide consistent warmth, lower operational costs, and support sustainability goals working towards a lower carbon footprint. The advanced technology ensures quiet, reliable operation across various models tailored to specific space sizes, such as the HR Series.

Proper installation and regular maintenance by certified technicians are key to optimal performance. These heaters not only meet but exceed modern heating solution expectations, offering significant energy savings and environmental benefits. Exploring their features and advantages reveals the pathway to a warmer, more efficient winter.

Understanding Warm Air Heating

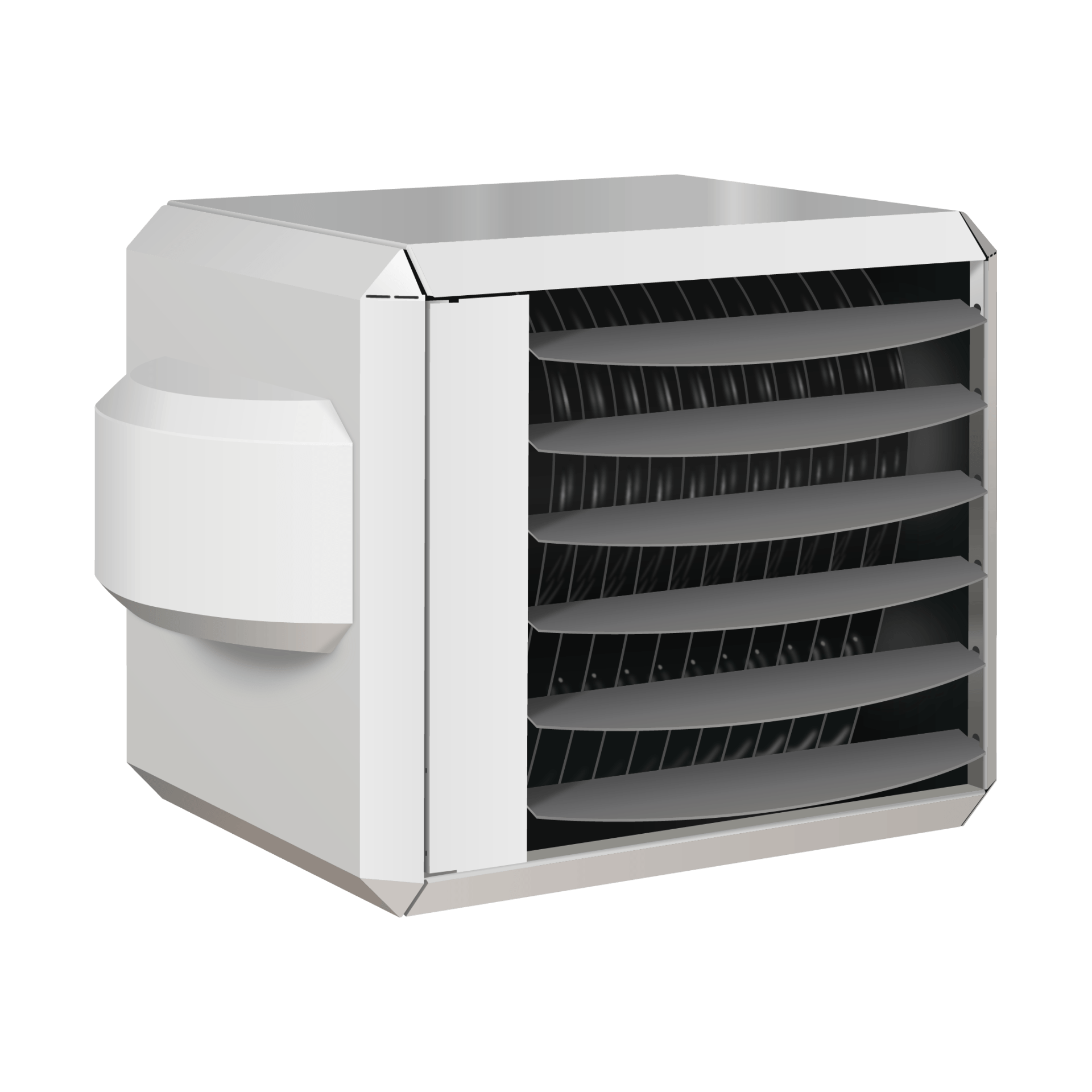

At its core, warm air heating involves drawing in cold air, heating it to a comfortable temperature, and then distributing it throughout your space, efficiently maintaining a cosy environment. This process becomes significantly more efficient with the introduction of a high efficiency condensing warm air heating system. Unlike traditional heating systems, these incorporate a condensing unit heater, which plays a pivotal role in their operation.

The hallmark of these systems is their ability to capture heat that would otherwise escape into the atmosphere in conventional heaters. By utilising a condensing unit heater, the system extracts heat from exhaust gases, leveraging this energy to warm air before it's circulated. This not only enhances the system's efficiency but also reduces energy consumption and operational costs.

Opting for a high efficiency condensing warm air heating system means you're investing in technology that's designed to maximise heat output from the fuel consumed. Whether powered by natural gas, propane, or other fuels, these systems ensure that a greater portion of the energy used is converted into usable heat for your space. This efficiency translates into lower emissions and a smaller carbon footprint, aligning with modern sustainability goals.

The Basics of Condensation

Understanding the basics of condensation is crucial, as it's the process that allows high efficiency condensing warm air heaters to capture and reuse heat effectively. At its core, condensation is the change of the physical state of matter from gas phase into liquid phase. This transformation is essential in the operation of condensing warm air heaters, making them a highly efficient heating solution.

When you're heating your space, these units work by burning fuel, typically natural gas, which generates warm air and exhaust gases as byproducts. In a standard heating system, these exhaust gases, still holding a considerable amount of heat, would simply be vented outside and lost. However, condensing warm air heaters are designed to capture this escaping heat. They cool the exhaust gases to a point where they condense into water, releasing the stored heat in the process. This captured heat is then reused to warm the air, significantly improving the heater's efficiency and lowering your carbon footprint.

Benefits of High Efficiency

High efficiency in warm air heaters offers significant savings on energy bills and reduces environmental impact. When you opt for a high efficiency condensing warm air heater, you're investing in a system that utilises less fuel to generate the same amount of heat as standard models. This efficiency is due to the heater's ability to condense water vapour in the exhaust gases, which releases latent heat that would otherwise be lost through the flue.

The beauty of high efficiency warm air heaters lies in their ability to deliver consistent warmth more economically and with fewer emissions. By choosing a unit with high efficiency, you're not only cutting down on your monthly expenses but also contributing to a cleaner environment by reducing your carbon footprint. These heaters are designed to maximise the efficiency of fuel use, whether it's natural gas or another source, ensuring that you get the most warmth for your pound.

Moreover, the advanced technology in high efficiency condensing heaters ensures that the system operates quietly and reliably, providing you with comfort without the constant reminder of a noisy heater. Investing in a warm air heater with high efficiency is a smart choice for both your wallet and the planet.

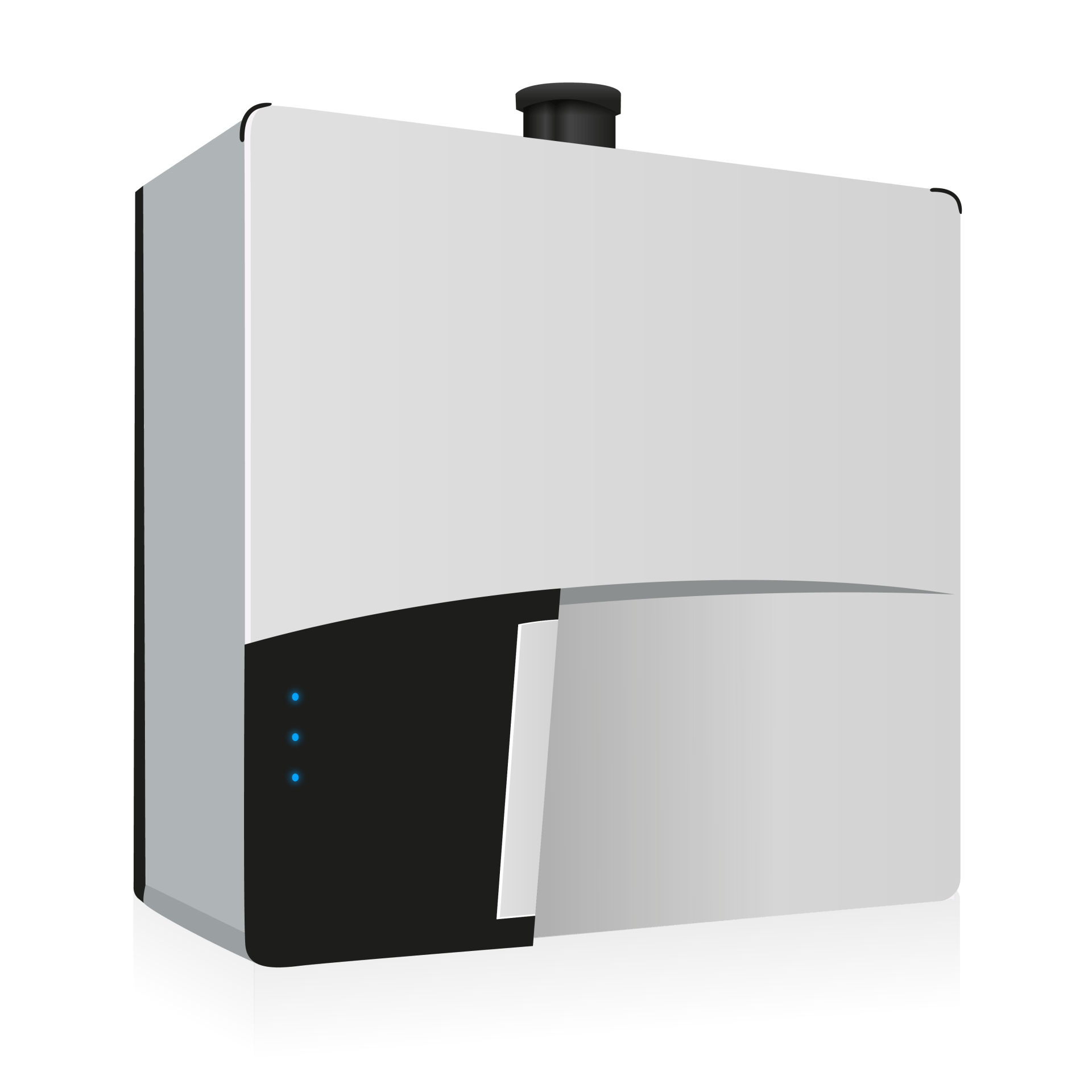

Exploring HR Series Heaters

Delving into the HR Series Heaters, you'll discover a lineup optimised for exceptional efficiency and environmental friendliness. These high efficiency condensing warm air heaters are designed to meet the needs of various spaces, ensuring your industry stays warm through the chilliest winters. The HR Series ranges from the HR 10 to the HR 120 models, each tailored to deliver precise heating solutions with commendable efficiency.

The core of these condensing heaters lies in their ability to condense the water vapour in the exhaust gases. This process releases additional heat, which is then used to warm the air more effectively. As a result, the HR Series offers significant energy savings and reduces carbon emissions, aligning with modern environmental standards.

Each model within the range of warm air heaters is crafted to serve a specific size and type of space, from smaller workshops to larger warehouses. Whether it's the compact HR 10 or the robust HR 120, the HR Series ensures optimal performance.

Installation and Maintenance

After exploring the features and benefits of the HR Series heaters, let's focus on how you can install and maintain these units to ensure their optimal performance. When it comes to installation, it's crucial to adhere strictly to the manufacturer's guidelines. This ensures that your condensing warm air heaters operate at their highest efficiency. Typically, these units should be installed by a certified technician who understands the nuances of working with high efficiency heating systems. Correct installation affects not just the unit's performance but also its longevity.

Maintenance, on the other hand, is key to keeping your condensing warm air heaters running smoothly. Regular checks are necessary to prevent any issues that could impact their efficiency. This involves cleaning the filters, checking the condensate drain for blockages, and ensuring that the burner and heat exchanger are free from debris. An annual inspection by a professional is recommended to assess the unit's overall condition and to perform any necessary adjustments or repairs.

Reducing Emissions, Boosting Warmth

By choosing HR Series condensing warm air heaters, you're not only enhancing the warmth in your space but also significantly reducing harmful emissions. These units are designed with high efficiency in mind, meaning they utilise fuel more completely than traditional heaters. This process not only generates more heat from the same amount of fuel but also results in fewer emissions being released into the environment.

Condensing warm air technology is pivotal in achieving these results. By condensing the water vapour in the exhaust gases, these heaters extract additional heat which would otherwise be wasted. This not only boosts the unit's efficiency but also contributes to a significant reduction in carbon footprint.

Moreover, reducing emissions isn't just about environmental responsibility. It's also about compliance with increasingly stringent regulations concerning energy use and pollution. By investing in high-efficiency condensing warm air heaters, you're future-proofing your heating system against tighter regulations, while also benefiting from lower operating costs.

Choosing the Right Model

Having understood the environmental and efficiency benefits of HR Series condensing warm air heaters, it's time to consider which model best fits your needs. With a range from the HR 10 to the HR 120, selecting the right condensing warm air heater is crucial for optimising your heating system's performance and efficiency.

First, assess your space's size and heating requirements. The HR 10 High Efficiency Condensing Warm Air Heater, for instance, is ideal for smaller areas, offering high efficiency in a compact design. For larger spaces, the HR 120 provides powerful heating capabilities, ensuring your environment stays warm all winter long.

Consider the specific needs of your industry. If your workspace involves high moisture or varying temperatures, you'll need a model that can efficiently condense warm air without compromising on performance. The HR Series is designed to meet diverse needs, with each model offering specific benefits such as low emissions and reduced energy consumption, aligning with a sustainable heating system approach.

Lastly, factor in the long-term running costs. High efficiency models like the HR Series may have a higher initial investment but lead to significant savings on energy bills over time. Choosing the right condensing warm air heater means balancing upfront costs with long-term benefits for your heating system.

Conclusion

Choosing the right condensing warm air heater, like those in the HR series, is vital for keeping your industry efficiently warm during winter. These units not only ensure a comfortable environment but also significantly cut down on energy costs and emissions, lowering your carbon footprint.

Remember, proper installation and regular maintenance are key to maximising their benefits. By investing in a high-efficiency model suited to your needs, you're opting for a sustainable, cost-effective heating solution that supports both your operational goals and the environment.

Can Condensing Warm Air Heaters Be Integrated With Existing HVAC Systems in Industrial Settings, or Do They Require a Standalone Installation?

Integrating condensing warm air heaters with existing HVAC systems in industrial environments offers a seamless and efficient solution to enhance energy efficiency without necessitating comprehensive system overhauls. This adaptability positions condensing warm air heaters as a versatile and cost-effective choice for businesses looking to upgrade their heating efficiency. These new generation heaters are designed to work in conjunction with current systems, providing a significant boost in performance and reducing energy consumption.

The process of integrating these advanced heaters into existing HVAC setups is straightforward, thanks to their design flexibility and compatibility. This ease of integration means that industries can achieve a higher level of energy efficiency by simply adding condensing warm air heaters to their current infrastructure. The result is a more efficient heating solution that leverages the best aspects of both traditional and modern heating technologies.

Condensing warm air heaters stand out for their exceptional efficiency, primarily due to their ability to recover heat from exhaust gases — a feature that traditional heating systems lack. By capturing and reusing this otherwise wasted energy, these heaters substantially lower the amount of fuel needed to maintain comfortable temperatures in large industrial spaces. Consequently, this leads to lower operational costs and a reduced environmental footprint, aligning with the growing demand for sustainable industrial practices.

Furthermore, the versatility of condensing warm air heaters means that industries are not forced into extensive and disruptive installation processes. Instead, they can upgrade their heating efficiency with minimal downtime, preserving productivity while simultaneously enhancing the workplace environment. This compatibility with existing HVAC systems ensures that the transition to higher efficiency heating is smooth and efficient, marking a smart investment for industries aiming to future-proof their operations.

In essence, the integration of condensing warm air heaters into existing HVAC systems represents a forward-thinking approach to industrial heating. It embodies a new generation of energy efficient solutions, offering a blend of high performance, cost savings, and environmental responsibility.

How Do Condensing Warm Air Heaters Perform in Extremely Cold Climates Where Temperatures Frequently Drop Below Freezing?

You'll find condensing warm air heaters perform exceptionally well in extremely cold climates, efficiently heating spaces even when temperatures drop below freezing. They're designed to maintain warmth and comfort no matter how cold it gets.

What Are the Long-Term Cost Savings Associated With Switching to a Condensing Warm Air Heater From a Traditional Heating System?

Switching to a condensing warm air heater from a traditional heating system represents a significant advancement towards greater energy efficiency and environmental sustainability. This new generation of heaters is designed with cutting-edge technology that substantially enhances their efficiency, leading to substantial long-term savings for users. With their ability to operate at higher efficiencies, these heaters ensure that a larger proportion of the heat generated is effectively utilized to warm your space, rather than being lost through exhaust gases as in older models.

The core advantage of condensing warm air heaters lies in their innovative use of condensing technology. By reclaiming heat from exhaust gases that would otherwise be wasted, these systems achieve a remarkable level of fuel efficiency. This efficiency translates directly into lower utility bills, as less energy is required to maintain comfortable indoor temperatures. Users can expect a noticeable reduction in their heating costs, making the investment in a condensing warm air heater a financially smart decision.

Can Condensing Warm Air Heaters Be Used in Environments With High Levels of Dust or Particulate Matter Without Compromising Efficiency or Air Quality?

Button

ButtonYes, you can use condensing warm air heaters in dusty environments without losing efficiency or air quality.

Condensing warm air heaters represent a new generation in heating technology, offering unparalleled energy efficiency and performance, even in challenging environments like those with high levels of dust. These advanced systems are engineered to cope with particulates without compromising on their core functions – maintaining optimal energy efficiency and upholding the highest standards of air quality.

How Does the Noise Level of Condensing Warm Air Heaters Compare to Traditional Warm Air Heating Systems?

Condensing warm air heaters, emblematic of new generation heating solutions, are not only acclaimed for their superior energy efficiency but also for their significantly quieter operation compared to traditional heating systems. This reduced noise output is a deliberate design consideration, aimed at enhancing the comfort and usability of spaces where noise levels can be a critical factor.

The quest for higher energy efficiency in heating technologies has led to innovations that inherently reduce mechanical noise. For instance, the internal components of condensing warm air heaters, such as fans and burners, are engineered to operate more smoothly and with less vibration, a common source of noise in older systems. Additionally, the process of condensing the exhaust gases, central to the operation of these heaters, is a relatively quiet one, contributing to their overall lower sound levels.

This focus on minimizing noise pollution does not come at the expense of heating performance. On the contrary, condensing warm air heaters maintain optimal heating efficiency by effectively capturing and reusing heat from exhaust gases—a process that significantly reduces wasted energy and, by extension, operational costs. This efficient use of energy is a hallmark of the new generation of heating systems, designed with both environmental sustainability and user experience in mind.

The quieter operation of condensing warm air heaters enhances the quality of the environment they're used in, making them particularly suitable for applications where noise is a concern, such as educational institutions, healthcare facilities, and open-plan offices. By providing a more comfortable and less disruptive atmosphere, these heaters support the well-being and productivity of occupants.

In conclusion, condensing warm air heaters represent a leap forward in heating technology, offering a blend of energy efficiency, environmental responsibility, and user-centric design. Their quieter operation is just one of the many benefits they bring, marking them as a superior choice for those looking to upgrade their heating systems without compromising on comfort or performance.

Share.

Comment.

Latest.